Scary - Noisy - Sparky

Considering I do a desk bound job I have quite a healthy tool collection in my shed, probably a combination of wanting to try and do house based DIY myself and a childhood messing around in my Dads garage. He was a cabinet maker so give me a drill or sander and I am happy.

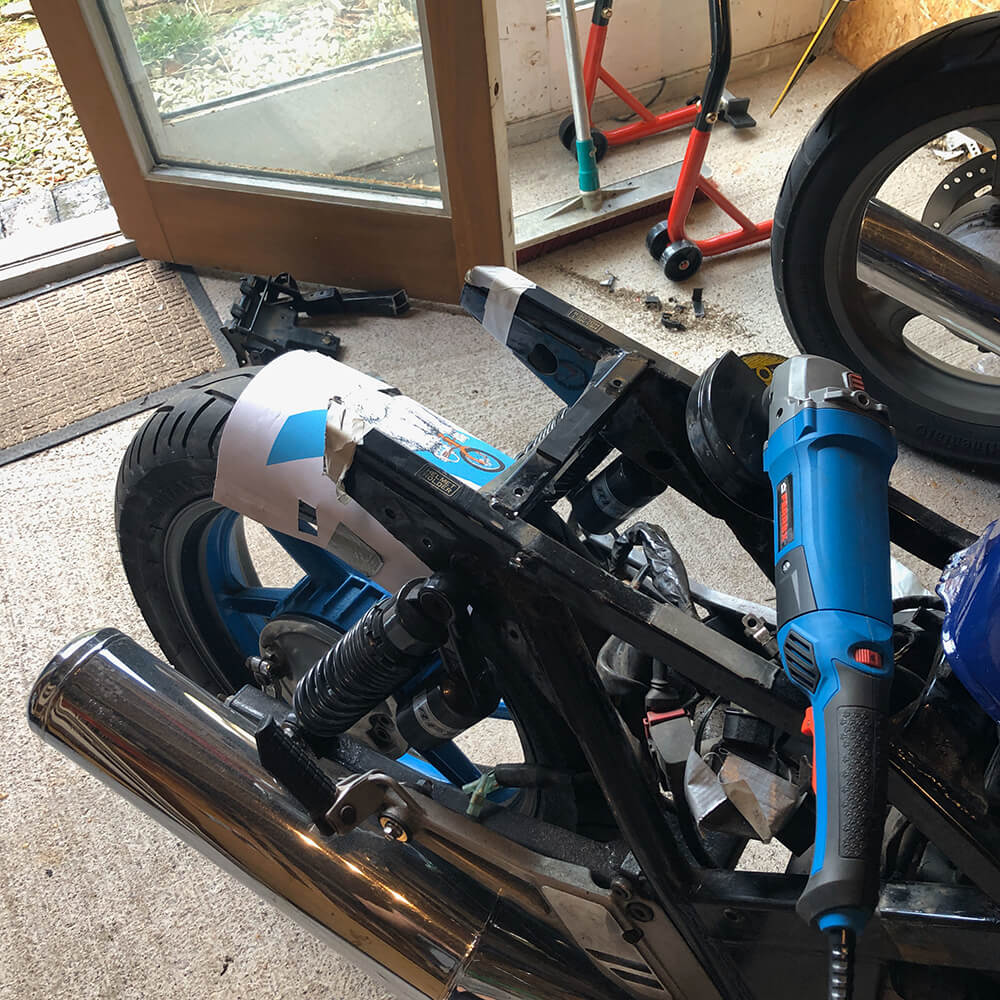

Well this is intimidating!

I hadn't encountered a proper need for an angle grinder before - cutting the back off the CB500 was going to be my first taste of them.

I have always had a healthy respect for circular saws, and am going to add the angle grinder to that list... what a noisy and generally destructive thing it is!

Measure twice cut once

One rule of woodwork that definitely applies is to double check your measurements. You can't glue pieces of bike frame back one easily and I have yet to learn to weld. :D

With things marked out and checked it was time to do the deed and, rather like a hot knife through butter the first cuts were made - there is no going back now.

With the frame chopped I can start looking at what needs to be fabricated, a rear hoop, electrics tray and a frame to mount the seat so it is horizontal.

Whilst I think about this I can be getting on with a seat cowel and pad.